In recent years, 3D printing has revolutionized the way we create and manufacture products.

Its rapid growth and widespread adoption can be attributed to its ability to produce complex designs with ease, reduce material waste, and save time in manufacturing processes.

Key Takeaways

Key Takeaways

- 3D printing can be used for a wide range of products, from jewelry to prosthetics to automotive parts, making it a versatile technology with endless possibilities.

- By using 3D printing, businesses can reduce material waste and save time in the manufacturing process, ultimately leading to cost savings and increased efficiency.

- While there are many opportunities for entrepreneurs in the 3D printing industry, it's important to conduct market research and identify a niche that is underserved or has room for innovation.

- Collaboration with other industries, such as software development or architecture, can lead to exciting new applications of 3D printing technology.

- As the technology continues to advance and become more accessible, it's likely that 3D printing will become an even more integral part of various industries in the future.

As the technology continues to advance, it’s becoming increasingly clear that 3D printing will play a vital role in the future of various industries.

For businesses looking to stay ahead of the curve, getting involved in the world of 3D printing offers numerous opportunities for innovation, customization, and increased efficiency.

In fact, according to a report by MarketsandMarkets, the global 3D printing market is expected to grow from $13.7 billion in 2021 to $34.8 billion by 2026 at a compound annual growth rate (CAGR) of 20.4%.

➤ MORE: Find out what other industries are on the rise?

With such promising prospects on the horizon, there’s never been a better time for businesses to explore the possibilities that 3D printing can offer.

This article will provide you with several exciting business ideas centered around this cutting-edge technology that you can use today to tap into its immense potential.

1. Custom 3D Printed Clothing & Wearable Art

2. On-Demand Product Manufacturing

3. Replacement Parts Production

4. Educational Workshops on 3D Printing Technologies

5. Customizable Promotional Products

6. Architectural and Interior Design Models

7. Custom 3D Printed Jewelry and Accessories

8. Medical Device Manufacturing: Custom 3D Printed Prosthetics and Dental Appliances

9. 3D Printed Art and Sculptures

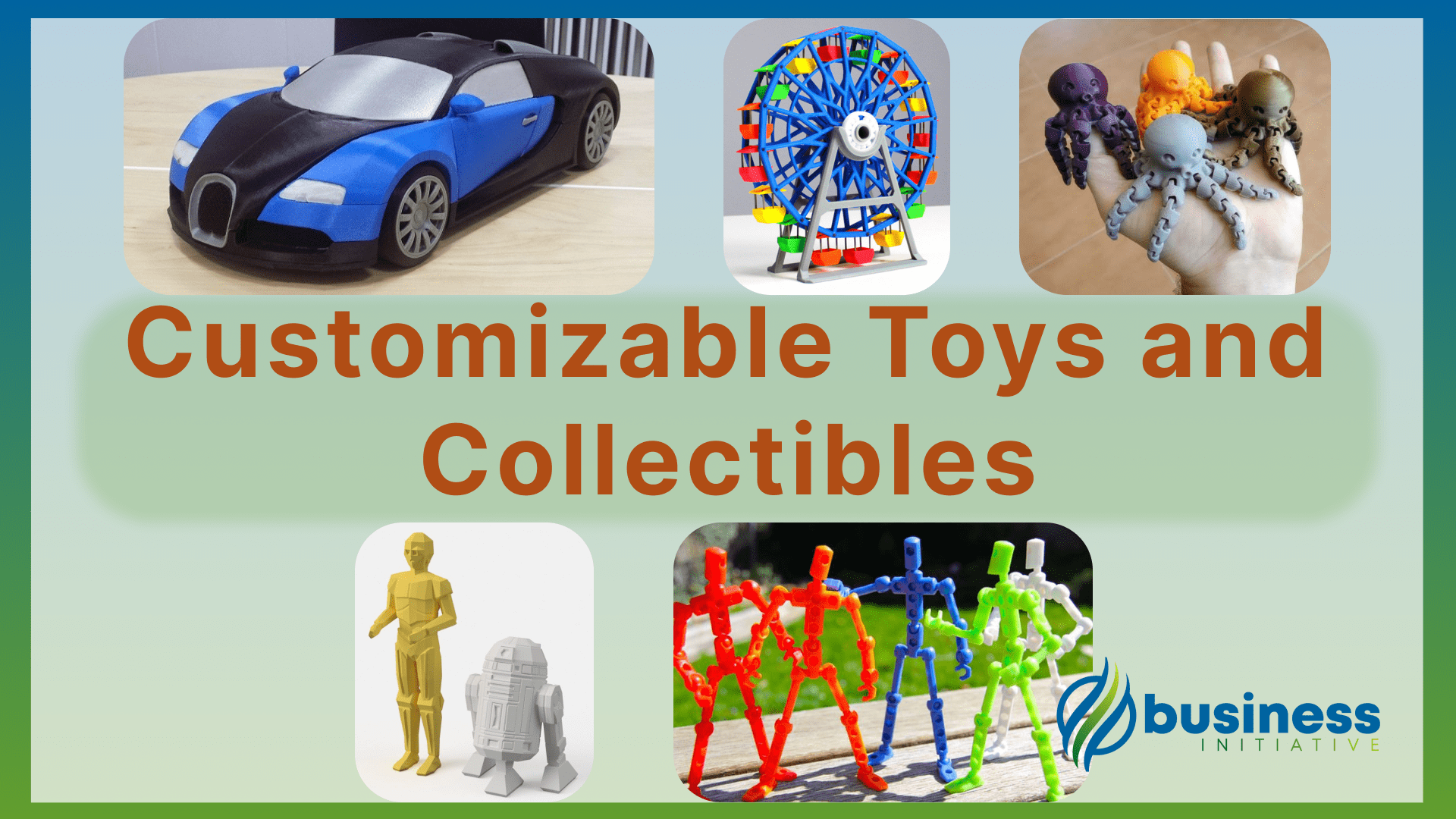

10. Customized Toys and Collectibles

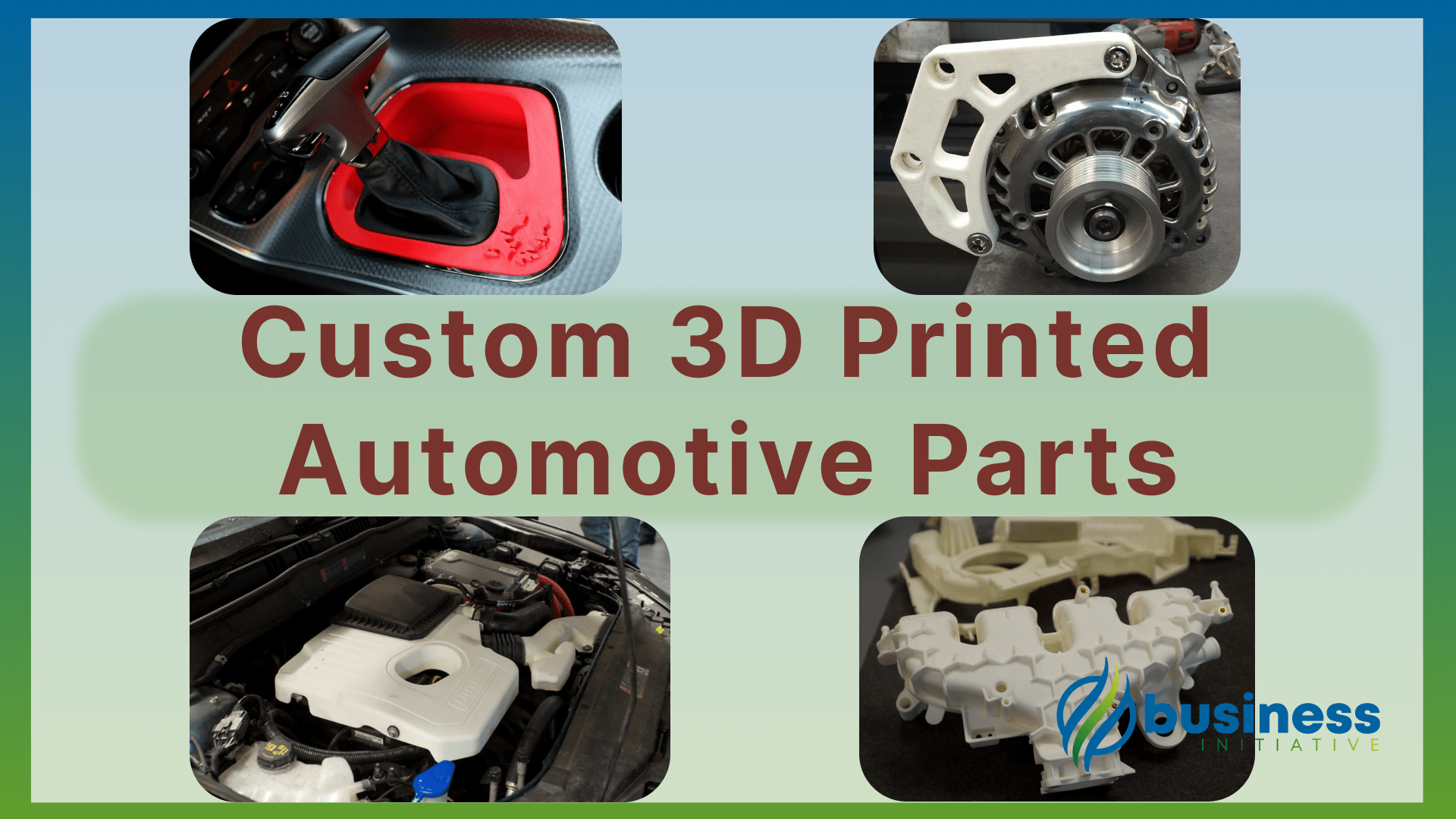

11. Custom 3D Printed Automotive Parts

12. Bespoke Furniture and Home Decor Items

13. 3D Printed Food

14. Eco-friendly products made from recycled materials

15. Rapid Prototyping and Custom Design Services

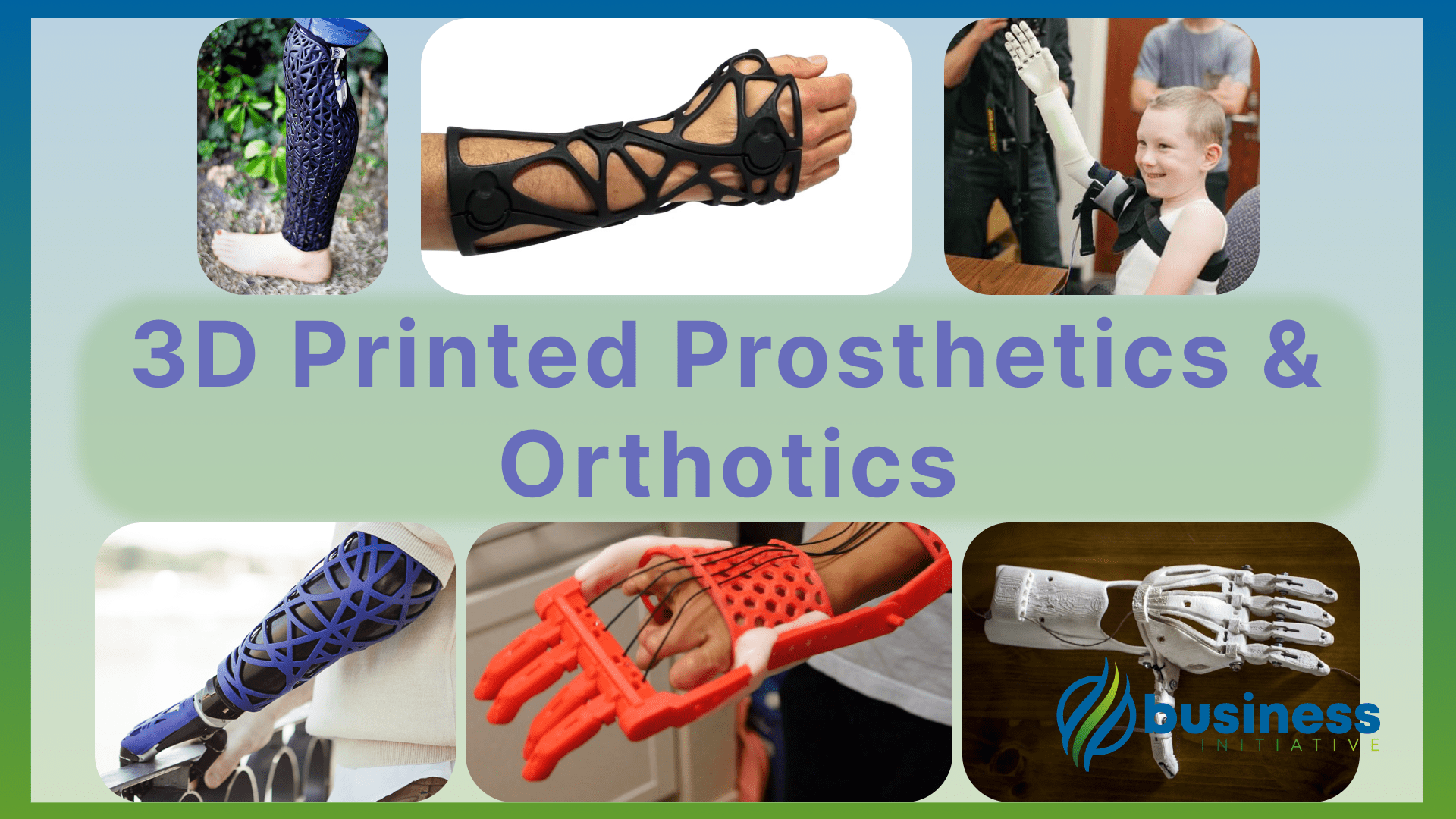

16. 3D Printed Prosthetics and Orthotics

17. Customized Foodservice Items and Kitchenware

18. Restoration and Preservation Services

19. Build a 3D Printing Community to Collaborate with Local Artists and Designers

20. Create Molds for Casting Using 3D Printing

21. Custom Cookie Cutters and Baking Tools

22. Integrate VR/AR Technologies with 3D Printing

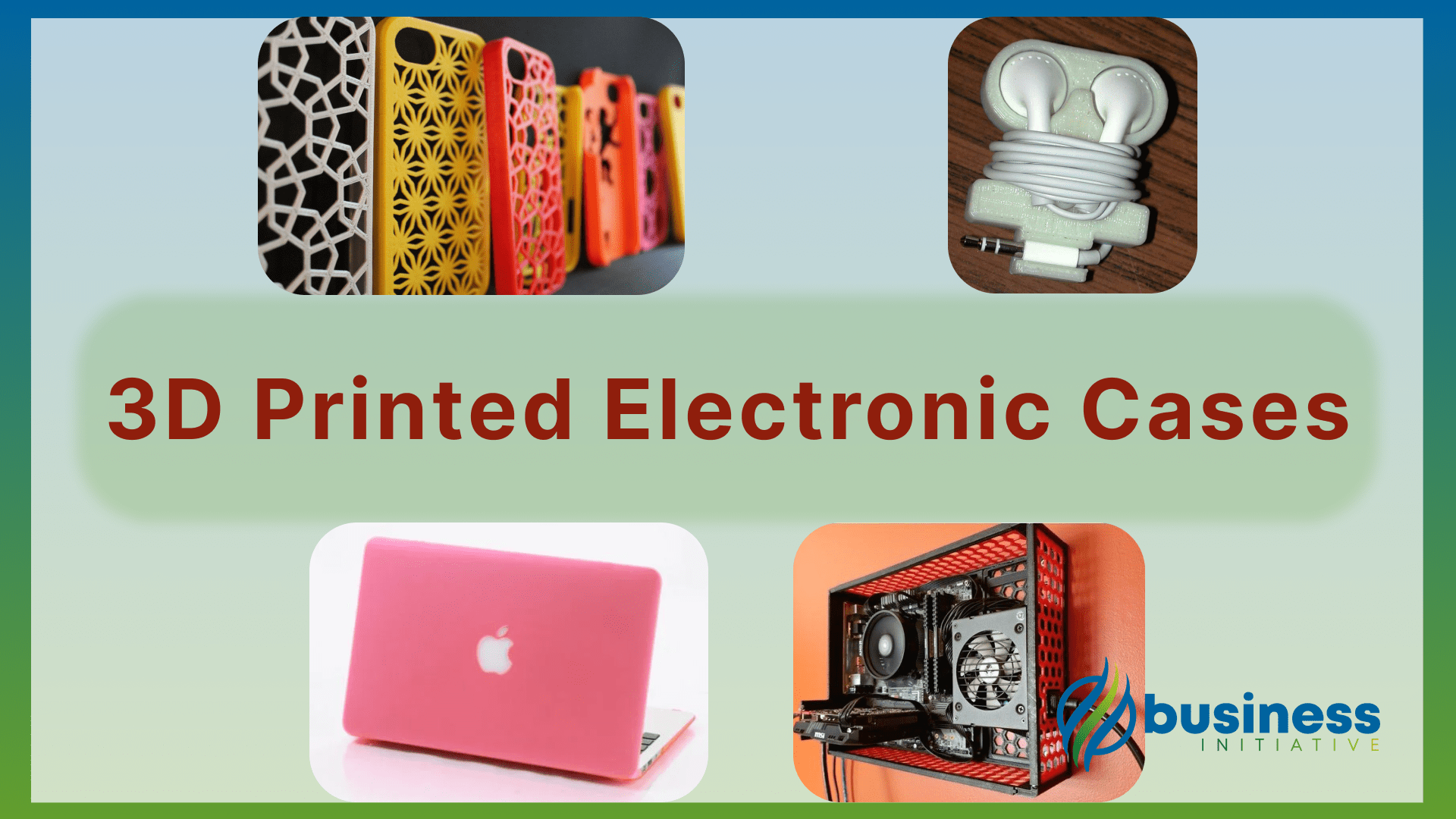

23. Customized Protective Cases for Electronics

24. Personalized Gifts and Souvenirs

25. Adaptive Clothing Solutions

26. Bicycle Customization Services

1. Custom 3D Printed Clothing & Wearable Art

Custom 3D printed fashion accessories is a business idea that focuses on offering unique and customizable fashion items such as belts, bags, or eyewear using 3D printing technology.

This business aims to cater to customers with a taste for distinctive style and those who value personalization and exclusivity in their fashion choices.

Key Steps to Success:

1. Research and choose a niche:

Identify the specific type of fashion accessories you want to focus on, such as eyewear, jewelry, or bags. Consider the market demand and competition in your chosen niche.

2. Invest in 3D printing technology:

Acquire a high-quality 3D printer and learn how to use it effectively. You may also need to invest in design software and materials for creating your products.

3. Create unique designs:

Develop a collection of original and customizable designs that will appeal to your target audience. You can either create the designs yourself or collaborate with designers.

4. Set up an online store:

Create a user-friendly website or use an e-commerce platform to showcase and sell your products. Make sure to include high-quality images and detailed descriptions of each item.

5. Promote your business:

Use social media, content marketing, and other digital marketing strategies to reach your target audience and generate interest in your products.

The Benefits:

- Growing demand for personalized products:

Consumers are increasingly looking for unique and personalized items, and 3D printed fashion accessories can cater to this demand.

- Low production costs:

3D printing technology allows for cost-effective production, as there is no need for expensive molds or large-scale manufacturing equipment.

- Quick turnaround time:

3D printing enables rapid prototyping and production, allowing businesses to quickly respond to customer requests and market trends.

- Environmentally friendly:

3D printing can be more sustainable than traditional manufacturing methods, as it produces less waste and uses fewer resources.

- Competitive advantage:

Offering custom 3D printed fashion accessories can help businesses stand out from competitors and attract a loyal customer base.

Take Initiative

How to Make Wearable Art Using 3D Printing

Sculpteo Fashion Accessory Services

The Future of Fashion Accessories with 3D Printing

2. On-Demand Product Manufacturing

Start a 3D printing service that produces custom products for clients on demand, reducing inventory costs and providing unique, tailored solutions to customers.

This business model allows for rapid prototyping, customization, and reduced waste, making it an attractive option for businesses looking to stay ahead in a competitive market.

Key Steps to Success:

1. Research the market and identify your target audience:

Understand the needs of your potential customers and the industries that could benefit from on-demand 3D printing services.

2. Acquire the necessary equipment:

Invest in high-quality 3D printers and materials to ensure the best possible results for your clients.

3. Develop a user-friendly platform:

Create a website or app that allows customers to easily upload their designs, choose materials, and place orders.

4. Market your services:

Use social media, online advertising, and networking events to promote your business and attract clients.

➤ MORE: Click here to find out how you can impove the way your company is seen by others!

The Benefits:

- Cost savings:

On-demand manufacturing reduces inventory costs and eliminates the need for large storage spaces.

- Customization:

3D printing allows for the creation of unique, tailored products that cater to individual customer preferences.

- Speed:

Rapid prototyping and production times enable businesses to bring products to market faster.

- Sustainability:

3D printing produces less waste than traditional manufacturing methods, making it an environmentally friendly option.

Take Initiative

Ultimaker: How to start a 3D printing business

3D Hubs: On-demand manufacturing guide

Sculpteo: 3D printing services

Shapeways: 3D printing marketplace

3. Replacement Parts Production

The replacement parts production business, specializes in manufacturing and supplying hard-to-find or discontinued parts for multiple industries.

Some of these markets include automotive, electronics, and home appliances.

Companies in this niche cater to customers needing specific components for product repair or maintenance.

By leveraging 3D printing technology to create these parts on demand, businesses can tap into a unique market, reduce wait times, and increase customer satisfaction.

Key Steps to Success:

1. Market research:

Identify the industries and specific products that have a demand for replacement parts.

This can be done through online forums, customer reviews, analyzing sales trends, or speaking with potential customers.

2. Invest in 3D printing technology:

Acquire a high-quality 3D printer capable of producing the desired parts.

Research different 3D printing technologies and materials to ensure the chosen printer can produce durable and functional parts.

3. Sourcing materials:

Find reliable suppliers for the raw materials needed to produce the replacement parts.

This may include metals, plastics, and electronic components.

4. Develop a digital parts library:

Create or source digital 3D models of the replacement parts.

This may involve designing the parts from scratch, reverse-engineering existing parts, or purchasing existing digital models.

5. Manufacturing:

Develop a production process that ensures the quality and consistency of the replacement parts.

This may involve investing in specialized machinery, hiring skilled workers, or partnering with an existing manufacturer.

6. Marketing and sales:

Create a strong online presence through a website and social media channels to showcase your products and reach potential customers.

You can also attend industry trade shows, collaborate with repair shops, and establish partnerships with other businesses in the industry.

7. Customer support:

Offer excellent customer service by providing detailed product information, easy ordering processes, and prompt responses to inquiries and concerns.

The Benefits:

- Filling a gap in the market:

By producing hard-to-find or discontinued replacement parts, businesses can cater to a niche market that is underserved by larger manufacturers.

- Customer loyalty and satisfaction:

Providing customers with the parts they need to keep their products functioning can lead to repeat business and positive word-of-mouth referrals.

- Reduce inventory costs:

By producing parts on demand, businesses can minimize the need for large inventories of physical parts, reducing storage and management costs.

- Sustainability:

Manufacturing replacement parts can contribute to a more sustainable economy by extending the lifespan of products and reducing the need for new purchases.

- Environmentally friendly:

3D printing can be a more sustainable option compared to traditional manufacturing, as it produces less waste and can utilize eco-friendly materials.

- Profitability:

As a specialized business, replacement parts production can command higher profit margins due to the unique nature of the products and the limited competition in the market.

Take Initiative

How to Start a 3D Printed Parts Business

Sculpteo Replacement Parts Service

3D Hubs - Guide to 3D Printing Technologies

Sculpteo - 3D Printing Materials Guide

Thingiverse - Digital Parts Library

GrabCAD - 3D Models and CAD Library

3DPrint.com - 3D Printing News and Industry Insights

4. Educational Workshops on 3D Printing Technologies

Educational workshops on 3D printing technologies provide hands-on training for schools, businesses, and individuals, covering design, materials, and applications.

By introducing 3D printing across various industries, these workshops bridge the knowledge gap and inspire innovation.

Offering classes on 3D printing, CAD software, and design principles can be a lucrative business opportunity, meeting the growing demand for skilled professionals while generating revenue.

Key Steps to Success:

1. Invest in 3D printing equipment:

Purchase or rent 3D printers, filament, and other necessary tools and materials for the workshops.

2. Identify the target audience:

Determine who would benefit most from your workshops or classes, such as students, professionals, hobbyists, or entrepreneurs.

Identify the age group and skill level of your workshop participants.

This will help you tailor the class content and activities to suit their needs.

3. Develop a curriculum:

Create a comprehensive and engaging curriculum that covers essential topics, such as 3D modeling, design principles, material selection, and printer operation.

Include hands-on activities and demonstrations to make the learning experience more interactive.

4. Find expert instructors:

Collaborate with knowledgable and skilled professionals in the 3D printing industry who can effectively teach the material to deliver engaging and informative sessions.

5. Secure a suitable location:

If offering in-person workshops or classes, look for a space that can comfortably accommodate your workshop participants and equipment, such as computers, 3D printers, and materials.

Schools, libraries, and community centers are ideal locations. Alternatively, consider offering online classes through video conferencing platforms or pre-recorded lessons.

6. Promote the workshops:

Promote your workshops through social media, local newspapers, industry forums, and community bulletin boards to reach your target audience and generate interest in your offerings.

Reach out to schools, libraries, and community centers directly to offer your services.

The Benefits:

- Meet growing demand:

As 3D printing technology becomes more widespread, the demand for skilled professionals in this field is increasing.

Offering educational workshops or classes can help meet this demand and position your business as a leader in the industry.

- Skill development:

Workshops can help employees develop new skills and stay up-to-date with the latest 3D printing technologies, increasing their productivity and value to the company.

- Foster innovation:

By teaching people about 3D printing and its potential applications, businesses can inspire creativity and innovation in their communities, which can lead to new business opportunities and collaborations.

- Create networking opportunities:

Hosting workshops can help businesses establish connections with industry professionals, potential clients, stakeholders, and suppliers - potentially leading to new business partnerships or collaborations.

➤ LEARN: The BENEFITS of starting a Partnership

- Build brand recognition and increase visibility:

Organizing high-quality educational workshops or classes can enhance a company’s credibility as an expert in the 3D printing industry, attracting new customers and partners.

- Diversify revenue streams:

Charging a fee for attending workshops can provide an additional source of income for your existing business, increasing its overall profitability

Take Initiative

Ultimaker’s 3D Printing Academy

5. Customizable Promotional Products

Customizable promotional products, such as 3D printed keychains, phone cases, and desk accessories, offer businesses a unique and memorable marketing solution to stand out from competitors and create a lasting impression on potential customers.

By leveraging 3D printing technology, businesses can provide personalized marketing materials tailored to their target audience, revolutionizing the way products are created and manufactured.

Key Steps to Success:

1. Identify your target audience:

Determine the demographic you want to reach with your promotional products.

This will help you choose the most appropriate items to customize.

2. Select the right 3D printing technology:

Research different 3D printing technologies, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), or Selective Laser Sintering (SLS), to find the best fit for your promotional products.

3. Design your promotional products:

You can either create your own 3D design using software like Tinkercad, Fusion 360, or Blender, or you can hire a professional 3D designer to create a custom design for your promotional item.

Make sure the design is functional, unique, visually appealing and represents your brand well.

➤ COMPARE: Registering as an LLC or a DBA?

4. Choose a 3D printing service:

There are many online 3D printing services available that can help you create your customized promotional items.

Some popular options include Shapeways, Sculpteo, and i.materialise.

These services allow you to upload your 3D design, choose the material, and have the item printed and shipped to you.

5. Choose the right materials:

3D printing services offer a wide range of materials to choose from, including plastics, metals, and ceramics.

Select materials that are appropriate for your promotional products, taking into consideration factors such as durability, appearance, and cost.

6. Order and distribute:

Once you have finalized the design and material, place your order with the 3D printing service.

They will print and ship the items to you.

You can also use your own 3D printer to produce your items.

You can then add any necessary finishing touches, such as painting or polishing, before distributing the promotional items to your customers, clients, or employees.

The Benefits:

- Stand out from the competition:

Customized promotional items created using 3D printing technology are unique and eye-catching, helping your business stand out from competitors who use traditional promotional materials.

- Create a lasting impression:

High-quality, customized promotional items are more likely to be kept and used by potential customers, ensuring that your brand remains in their minds for a longer time.

- Increase brand recognition:

By offering promotional products that are tailored to your target audience, you can increase brand recognition and build a stronger connection with potential customers.

- Environmentally friendly:

3D printing is an additive manufacturing process, meaning it only uses the material necessary to create the item, resulting in less waste compared to traditional manufacturing methods.

- Cost-effective marketing:

3D printing allows for small-batch production of promotional items at a lower cost than traditional manufacturing methods.

This means you can order the exact number of promotional items you need without worrying about excess inventory or high production costs, making it an affordable marketing solution for businesses of all sizes.

Take Initiative

Custom 3D Printed Promotional Items

Ultimaker: Choosing the Right 3D Printing Technology

Tinkercad: Free 3D Modeling Software

Sculpteo: Guide to 3D Printing Materials

Promotional Products Association International (PPAI)

3D Hubs: How to Choose the Right 3D Printing Material

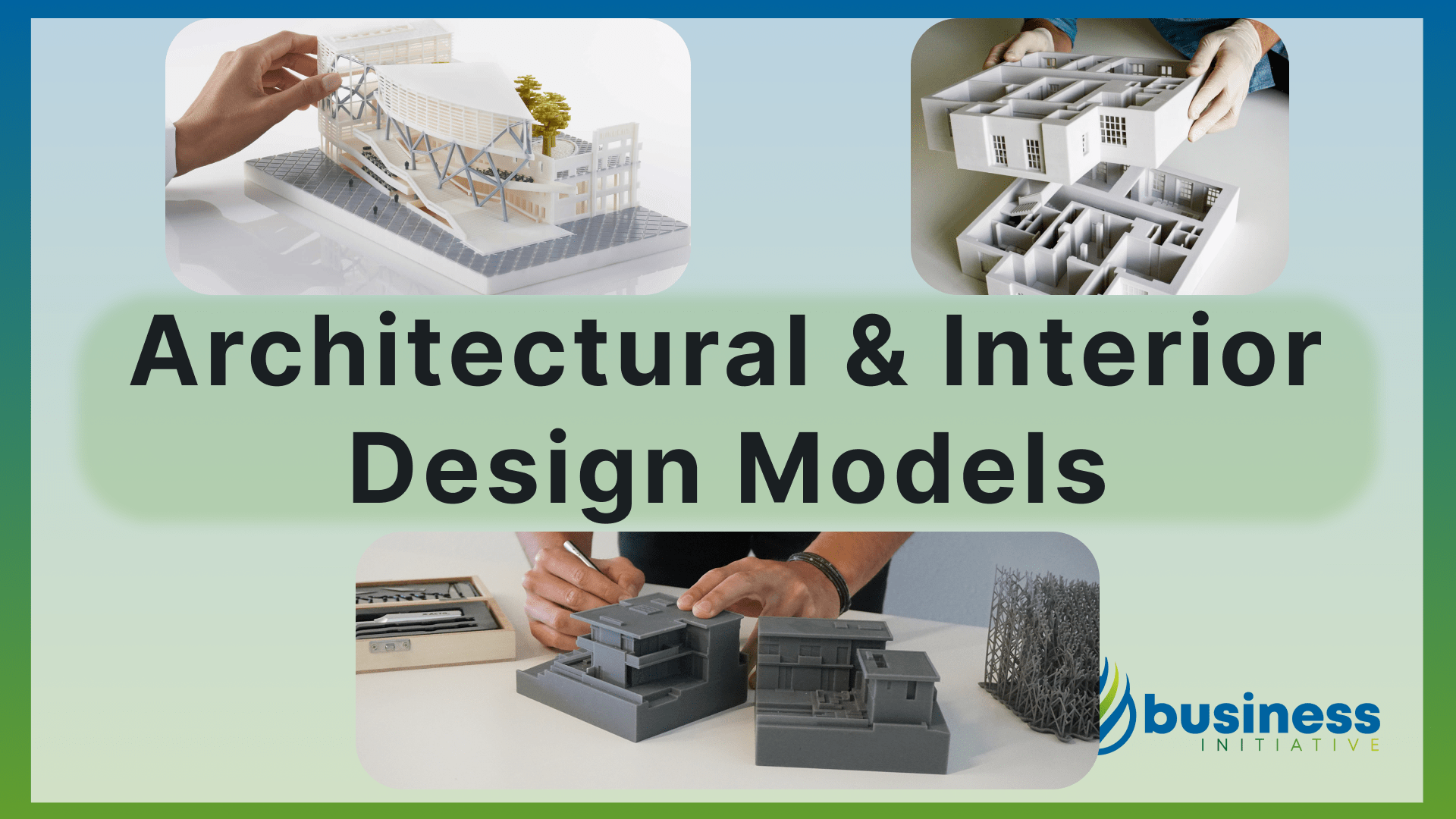

6. Architectural and Interior Design Models

Offering 3D printing services for creating detailed scale models of architectural designs presents a lucrative business opportunity, catering to architects, interior designers, and construction companies.

These models help clients visualize the final product, enable designers to identify and resolve potential issues before construction, and provide a cost-effective solution for communicating design concepts effectively.

Key Steps to Success:

1. Acquire high-quality 3D printers:

Invest in reliable and precise 3D printers that can handle various materials and sizes.

Research the best 3D printers, modeling software, and materials for accurate architectural models and interior design applications.

2. Develop expertise in 3D modeling software:

Gain knowledge in architectural design principles, 3D modeling techniques, and software tools. Consider taking courses or certifications in these areas to enhance credibility.

Check out programs for AutoCAD, SketchUp, or Rhino, to create accurate and detailed models.

3. Establish relationships with industry experts:

Network with architects, interior designers, and construction companies in the industry and showcase your 3D printing capabilities.

Attend conferences, trade shows, and networking events to connect with architects, engineers, and real estate developers who may require your services.

Offer competitive pricing and fast turnaround times to attract clients.

4. Create a portfolio:

Develop a diverse portfolio of your completed projects and concepts to demonstrate your skills and expertise in 3D printing architectural and interior design models.

Showcase various types of architectural models, including residential, commercial, and industrial projects.

This will help potential clients understand the quality and range of services offered.

5. Establish a strong online presence:

Develop a professional website and social media profiles to showcase your portfolio, share industry news, and engage with potential clients.

The Benefits:

- Enhanced visualization:

3D printed models provide clients with a tangible representation of their project, making it easier for them to understand and approve the design.

- Improved communication:

Physical models facilitate better communication between architects, designers, and stakeholders, leading to more effective collaboration and decision-making and fewer misunderstandings and design revisions.

- Cost and time savings:

3D printing technology allows for more affordable and efficient production of architectural models compared to traditional methods.

By identifying and resolving design issues before construction begins, you can save time and money on the project.

- Competitive advantage:

By providing architectural modeling services, businesses can diversify their offerings and tap into new revenue streams.

Offering high-quality 3D printed models can set your business apart from competitors and attract more clients.

- Increased demand:

With the growing popularity of 3D printing technology, there is a rising demand for accurate and detailed architectural models.

Take Initiative

Guide to Architectural Models with 3D Printing

Shapeways Architecture & Design Services

Best 3D Printers for Architects

3D Printing for Architecture: A Beginner’s Guide

7. Custom 3D Printed Jewelry and Accessories

Custom 3D printed jewelry and accessories offer a unique and growing trend in the fashion industry, catering to customers seeking personalized, one-of-a-kind pieces.

By incorporating 3D printing technology, businesses can create intricate designs and customizable items such as rings, pendants, and earrings, appealing to a wide range of individual preferences.

This innovative business idea is ideal for entrepreneurs passionate about creativity, design, and the jewelry industry.

Key Steps to Success:

1. Research and learn about 3D printing:

Familiarize yourself with the basics of 3D printing technology, materials, and software.

Understand the market trends and customer preferences to create appealing designs.

This will help you understand the process and make informed decisions when setting up your business.

2. Invest in 3D printing equipment:

Purchase or lease a 3D printer suitable for jewelry and accessories.

Consider factors such as print resolution, build volume, and material compatibility.

In addition to the printer, you’ll also need materials suitable for jewelry making, such as precious metals, gemstones, and other materials.

3. Develop your skills:

Enhance your design and 3D modeling skills by taking online courses or attending workshops.

Practice using design software like Blender, Rhino, or Tinkercad.

4. Design or source 3D models:

Create your own 3D models using CAD software or source them from online marketplaces like Shapeways or Thingiverse.

You can also collaborate with designers to create exclusive designs for your business.

5. Create a portfolio:

Design a range of jewelry pieces to showcase your skills and creativity.

This will help attract potential customers and demonstrate your capabilities.

6. Set up an online store:

Create a website or use an e-commerce platform like Shopify or Etsy to showcase and sell your products.

Make sure to include high-quality images and detailed descriptions of your items.

Include an e-commerce platform to facilitate online orders and payments.

➤ MORE: Optimize your payment processing TODAY!

7. Promote your business:

Use social media, email marketing, other digital marketing strategies, and local events to reach your target audience and generate interest in your products.

The Benefits:

- Unique and customizable products:

3D printing allows for intricate and complex designs that are difficult to achieve through traditional manufacturing methods.

This allows businesses to stand out in a competitive market by offering one-of-a-kind pieces tailored to individual preferences.

- Innovative technology:

Utilizing 3D printing technology enables businesses to create intricate designs and use a variety of materials, positioning them as innovative leaders in the industry.

- Lower production costs:

3D printing can significantly reduce production costs, as it eliminates the need for molds and other expensive manufacturing tools.

This allows businesses to offer high-quality products at competitive prices.

- Higher profit margins:

Customized pieces often command higher prices due to their uniqueness and the craftsmanship involved, leading to increased profit margins.

- Faster production times:

3D printing technology enables rapid prototyping and production, allowing businesses to quickly respond to customer demands and market trends.

- Environmentally friendly:

3D printing can be more sustainable than traditional manufacturing methods, as it produces less waste and uses fewer resources.

- Niche market appeal and repeat customers:

By offering custom 3D printed jewelry and accessories, businesses can tap into a niche market of customers looking for unique and personalized fashion items.

Personalized jewelry caters to customers’ desires for individuality and self-expression, resulting in higher satisfaction and repeat business.

Take Initiative

How to Design and Sell 3D Printed Jewelry

Jweel - Customizable 3D Printed Jewelry Platform

Sculpteo Jewelry & Accessories

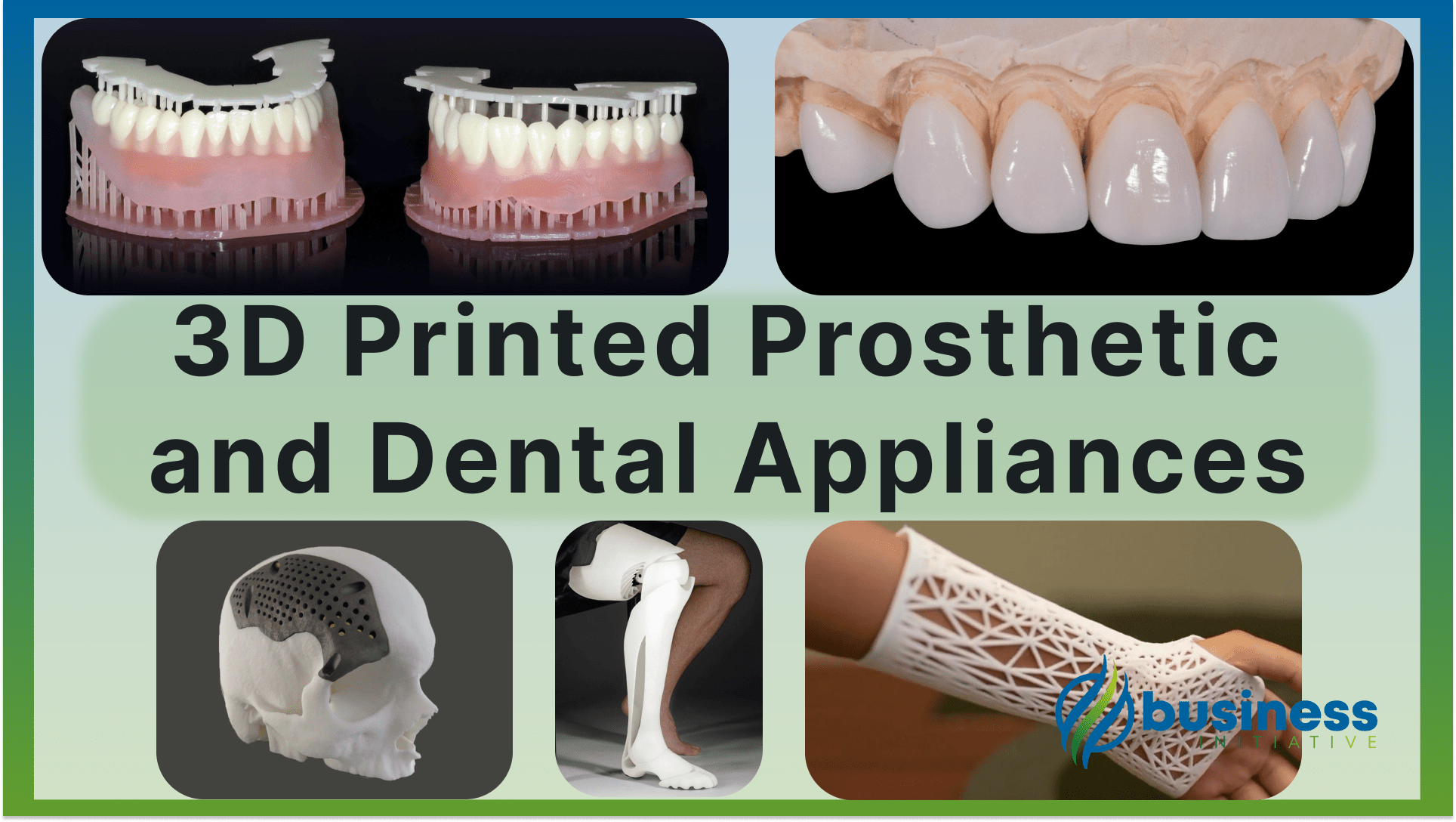

8. Medical Device Manufacturing: Custom 3D Printed Prosthesis and Dental Appliances

The medical device manufacturing industry is continuously evolving with promising advancements like 3D printing technology, allowing for the creation of custom-fit medical devices such as prosthetics and dental appliances tailored to individual patients’ needs.

By leveraging 3D printing, businesses can offer personalized solutions that improve patient outcomes and satisfaction while reducing production costs and waste.

This makes for a lucrative business opportunity to expand into the medical field by offering customized medical devices or assistive tools, ultimately improving the lives of patients with various medical conditions and disabilities and providing a valuable service to healthcare professionals.

Key Steps to Success:

1. Invest in 3D printing technology:

Acquire high-quality 3D printers specifically designed for medical device manufacturing.

These printers must meet industry standards and be capable of using biocompatible materials to produce precision, durable, safe, and effective devices.

2. Research and development:

Invest time in understanding the medical devices and assistive tools market.

Identify the specific needs of patients and healthcare professionals, and explore the possibilities of 3D printing technology in addressing those needs.

3. Develop expertise:

Hire or train staff with expertise in 3D printing, medical device design, and relevant software tools.

This will ensure that your business can create custom-fit devices that meet the specific needs of each patient.

4. Collaborate with healthcare professionals:

Establish partnerships with doctors, dentists, orthopedic specialists, and other healthcare professionals who can provide patient data and valuable insights to inform the design and production of your custom medical devices.

5. Ensure regulatory compliance:

Familiarize yourself with the regulatory requirements and certifications for medical device manufacturing in your region and ensure that your business adheres to all necessary standards and certifications.

6. Obtain necessary certifications and licenses:

Ensure compliance with local, national, and international regulations.

This may include obtaining certifications, licenses, and adhering to quality control standards, such as ISO 13485 for medical device quality management systems.

7. Create prototypes and refine designs:

Test and improve your product designs to ensure they meet the needs of your target market.

8. Marketing and sales:

Develop a marketing strategy to promote your products to healthcare professionals, hospitals, clinics, patients, and other potential customers.

Establish a sales network or collaborate with existing distributors to reach your target audience.

The Benefits:

- Growing market:

The demand for customized medical devices and assistive tools is on the rise, driven by an aging population and advancements in medical technology.

Offering innovative solutions to healthcare professionals can help build a strong reputation and establish the business as a leader in the industry.

- Improved patient outcomes:

Custom-fit medical devices can provide better comfort and functionality for patients, leading to improved outcomes and overall satisfaction.

- Reduced production costs and time:

3D printing technology allows for on-demand manufacturing, reducing the need for large inventories, minimizing waste, and eliminating the need for expensive molds and tooling.

It also allows for quicker turnaround times, enabling businesses to respond to customer needs more efficiently and stay ahead of competitors.

- Competitive advantage:

Offering personalized medical devices can set your business apart from competitors and attract a loyal customer base.

3D printing technology allows for faster production and customization of medical devices, providing a competitive advantage over traditional manufacturing methods.

- Scalability:

Expanding into the medical field can open up new revenue streams and increase profitability.

As 3D printing technology continues to advance, businesses can easily scale their operations to meet growing demand for custom medical devices.

- Positive impact:

By providing high-quality, customized medical devices, businesses can make a meaningful difference in the lives of patients and contribute to the overall improvement of healthcare services.

Take Initiative

Forbes: The Future of 3D Printing in Healthcare

3D Printing in Medicine: An Introductory Guide

Medical Applications for 3D Printing: Current and Projected Uses

FDA Guidance on 3D Printing Medical Devices

Additive Manufacturing for Medical Devices

FDA’s Role in 3D Printing Medical Devices

National Institutes of Health: 3D Printing in Medicine

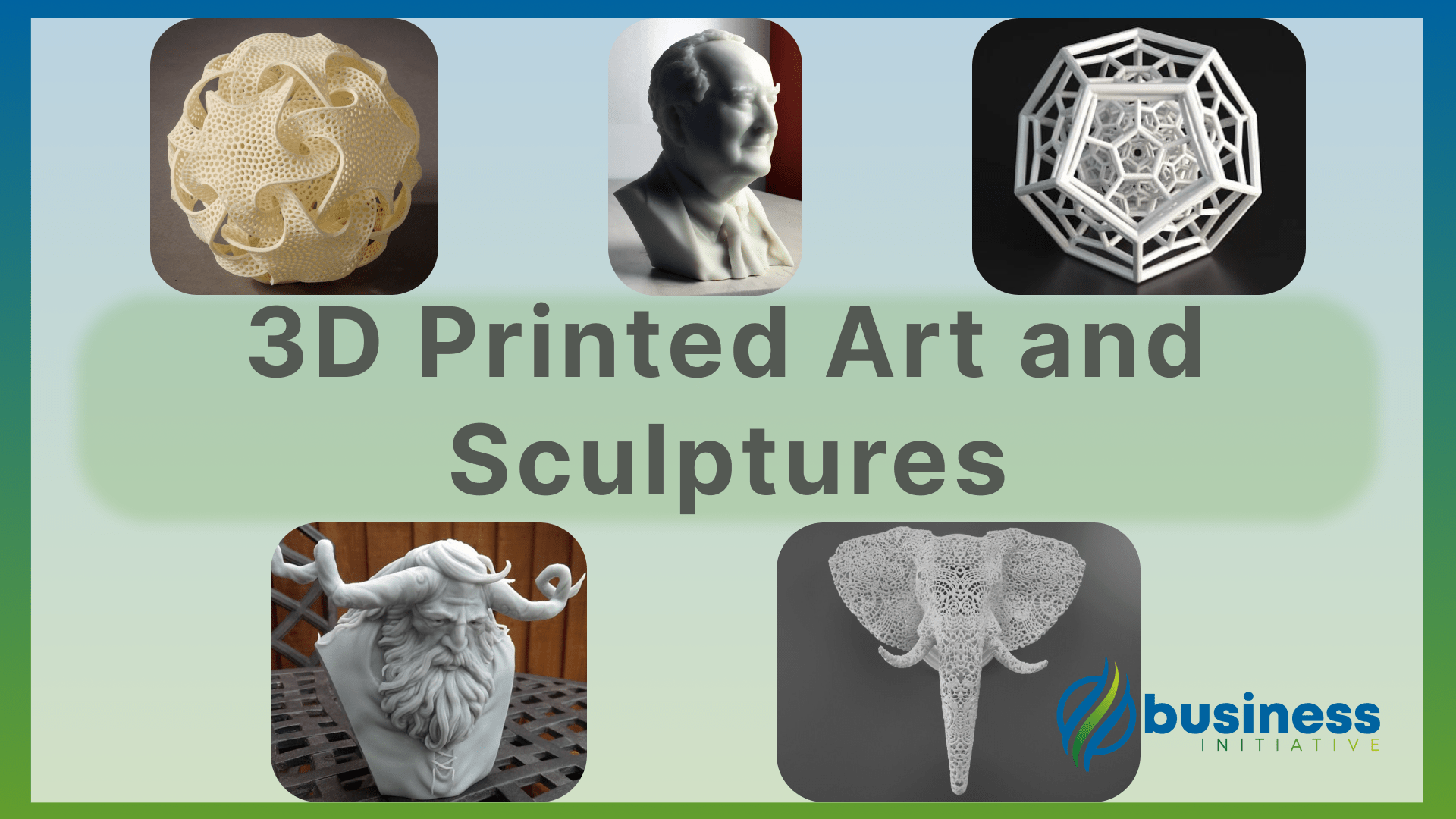

9. 3D Printed Art and Sculptures

3D printed art and sculptures are an innovative way to create unique, custom-made pieces for interior design, corporate installations, or personal collections.

By utilizing 3D printing technology, businesses can offer a wide range of designs and materials to cater to their clients’ preferences, making it an attractive option for those looking to stand out in the art world.

Key Steps to Success:

1. Research and invest in 3D printing equipment:

To start, you’ll need to invest in a high-quality 3D printer and materials.

Research the best options for your budget and needs, considering factors like print size, material compatibility, and resolution.

2. Develop your design skills:

To create stunning 3D printed art, you’ll need to have a strong foundation in design principles and software.

Familiarize yourself with 3D modeling programs like Blender, SketchUp, or Tinkercad, and consider taking courses or workshops to improve your skills.

3. Create a portfolio:

Showcase your unique designs and capabilities by creating a portfolio of your work.

This will help potential clients understand the range and quality of your offerings.

4. Market your business:

Establish a strong online presence through a website and social media platforms.

Attend art shows, galleries, and networking events to connect with potential clients and collaborators.

5. Collaborate with artists and designers:

Partner with other artists and designers to expand your offerings and reach a wider audience.

This can lead to exciting collaborative projects and help establish your reputation in the industry.

The Benefits:

- Unique offerings:

3D printed art and sculptures allow businesses to offer one-of-a-kind pieces that cater to a wide range of tastes and styles.

- Customization:

Clients can request specific designs, materials, and colors, making the final product truly unique and tailored to their needs.

- Efficiency:

3D printing technology enables faster production times compared to traditional art-making methods, allowing businesses to fulfill orders more quickly and efficiently.

- Sustainability:

Many 3D printers use eco-friendly materials, making this a more sustainable option for creating art and sculptures.

- Innovation:

Embracing 3D printing technology positions your business as an innovative leader in the art world, attracting clients who value cutting-edge design and technology.

Take Initiative

Sculpteo Art & Sculpture Services

10. Customized Toys and Collectibles

Customized toys and collectibles are unique, personalized items created for collectors, fans of popular franchises, or anyone who appreciates one-of-a-kind products.

By using 3D printing technology, businesses can produce detailed, high-quality toys, action figures, or collectible items tailored to individual preferences.

This niche market has a strong potential for growth, as consumers increasingly seek personalized experiences and products.

Key Steps to Success:

1. Research the market:

Identify your target audience and their preferences. Determine which franchises, characters, or themes are popular and in demand.

2. Invest in 3D printing technology:

Acquire a 3D printer and learn how to use it. Research different materials and printing techniques to ensure the best quality for your products.

3. Create unique designs:

Develop your own designs or collaborate with artists to create exclusive, customized items.

Use 3D modeling software to create digital models of your designs.

4. Market your products:

Build a strong online presence through social media, a website, and e-commerce platforms.

Attend conventions, trade shows, and other events to showcase your products and connect with potential customers.

5. Ensure legal compliance:

Obtain necessary licenses and permissions for using copyrighted characters or designs. Always respect intellectual property rights.

➤ MORE: Get copyright approval FAST - Step-by-step Process

The Benefits:

- Growing demand for personalized products:

Consumers are increasingly seeking unique, customized items that reflect their interests and personalities.

Customized toys and collectibles cater to this demand, offering a distinctive product that stands out in the market.

- High-profit potential:

As these products are tailored to individual preferences, customers may be willing to pay a premium for them.

This can lead to higher profit margins compared to mass-produced items.

- Creative freedom:

This business model allows entrepreneurs to explore their creativity and passion for popular franchises, characters, or themes.

It also offers the opportunity to collaborate with artists and designers, fostering a community of like-minded individuals.

- Scalability:

As 3D printing technology advances, production costs may decrease, allowing businesses to scale up and reach a wider audience.

Take Initiative

Ultimaker: 3D Printing for Toys and Collectibles

3D Printing Industry: A Guide to 3D Printing Toys

Shapeways: Custom 3D Printed Collectibles

Sculpteo: Intellectual Property and 3D Printing

Creating Custom 3D Printed Toys

Toybox Labs - Customizable 3D Printed Toys Platform

Sculpteo Toy & Collectible Services

11. Custom 3D Printed Automotive Parts

Custom 3D printed automotive parts cater to car enthusiasts, mechanics, and automotive restoration experts by providing unique, high-quality, and affordable components for both classic and modern vehicles.

Utilizing 3D printing technology, businesses can produce custom or rare parts that are otherwise difficult to find or expensive to manufacture, saving clients time, money, and effort in sourcing or fabricating the parts they need.

Key Steps to Success:

1. Research and invest in a suitable 3D printer:

Invest in a high-quality 3D printer that can handle various materials, such as plastic, metal, and composite materials.

Research the best 3D printers for automotive applications and choose one that fits your budget and requirements while being capable of producing durable and accurate parts.

2. Research and identify the target market:

Understand the needs and preferences of car enthusiasts and individuals searching for specific automotive parts.

This will help in determining the most sought-after components and accessories.

3. Develop or source 3D models:

Obtain accurate 3D models of the automotive parts you plan to produce.

You can create these models yourself using CAD software or source them from online repositories or clients.

4. Implement quality control measures:

Ensure that each printed part meets high standards of quality, durability, and accuracy.

This will help in building a strong reputation and gaining customer trust.

5. Test and refine your 3D printed parts:

Print prototypes of your custom automotive parts and test them for fit, function, and durability.

Refine your designs and printing settings as needed to ensure the final product meets the required specifications.

6. Establish an online presence:

Set up a website and social media profiles to showcase your products, share customer testimonials, and engage with potential clients.

Offer an easy-to-use platform for customers to place orders and communicate their specific requirements.

7. Market your services:

Promote your custom 3D printed automotive parts business to potential clients, such as car enthusiasts, mechanics, and restoration shops.

Use online marketing, social media, and local networking events to reach your target audience.

The Benefits:

- Growing demand:

The automotive industry is continuously evolving, and there is a growing demand for custom, unique, and hard-to-find parts and accessories.

- Fulfill niche market needs:

Custom 3D printed automotive parts cater to a specific market segment that requires unique or hard-to-find parts.

By offering this service, businesses can tap into a profitable niche with less competition.

- Environmentally friendly:

3D printing is a more sustainable manufacturing method, as it produces less waste and consumes fewer resources compared to traditional methods.

- Offer cost-effective solutions:

Traditional manufacturing methods can be expensive and time-consuming, especially for small production runs or one-off parts.

3D printing allows businesses to produce parts at a lower cost and faster turnaround time, making it an attractive option for clients.

- Stay ahead of the competition:

Embracing 3D printing technology can help businesses stay ahead of competitors who are still relying on traditional manufacturing methods.

This can lead to increased market share and a reputation for innovation.

- Faster turnaround times:

Traditional manufacturing methods can take weeks or even months to produce custom parts.

3D printing significantly reduces production time, allowing businesses to fulfill orders more quickly.

- Expand product offerings:

By offering custom 3D printed automotive parts, businesses can expand their product offerings and attract new clients who may not have been interested in their existing services.

Take Initiative

Ultimaker: 3D Printing in the Automotive Industry

Automotive Applications for 3D Printing

Sculpteo: 3D Printing for Automotive

Shapeways Automotive Parts Marketplace

All3DP: Best 3D Printers for Automotive Parts

GrabCAD: Automotive 3D Printing Models

12. Bespoke Furniture and Home Decor Items

Bespoke furniture and home decor items are custom-made pieces tailored to the specific tastes and preferences of individual customers.

By utilizing 3D printing technology, businesses can create unique, personalized furniture and home decor items that reflect customers’ styles and enhance the overall aesthetic of their living spaces.

Key Steps to Success:

1. Identify target market:

Determine the ideal customer base for your bespoke furniture and home decor items, such as homeowners, interior designers, or businesses seeking to create a unique atmosphere.

2. Invest in 3D printing technology:

Acquire high-quality 3D printers and materials suitable for creating furniture and home decor items.

3. Develop design skills:

Hire or collaborate with talented designers who can create custom designs based on customer preferences and current trends.

4. Create a user-friendly platform:

Develop a website or app that allows customers to easily browse your product offerings, customize their selections, and place orders.

5. Promote your business:

Utilize social media, online advertising, and local events to showcase your unique products and attract potential customers.

The Benefits:

- Stand out from competitors:

Offering bespoke furniture and home decor items can help businesses differentiate themselves from competitors and attract customers seeking unique, personalized products.

- Increase customer satisfaction:

By providing customers with the ability to customize their purchases, businesses can enhance customer satisfaction and encourage repeat business.

- Expand product offerings:

3D printing technology allows businesses to create a wide range of products, from small decorative items to larger furniture pieces, providing customers with a diverse selection to choose from.

- Reduce waste:

3D printing enables businesses to produce items on-demand, reducing the need for excess inventory and minimizing waste.

- Adapt to changing trends:

As design trends evolve, businesses can easily update their product offerings to stay current and appeal to new customers.

Take Initiative

Designing Furniture with 3D Printing

Kwambio Customizable Furniture Platform

13. 3D Printed Food

3D printed food is an innovative approach to food production that combines culinary art, technology, and customization.

By using 3D printers specifically designed for food, businesses can create visually appealing and personalized dishes for their customers.

This technology has the potential to revolutionize the food industry, offering new opportunities for creativity, efficiency, and customer satisfaction.

Key Steps to Success:

1. Research and choose a 3D food printer:

There are several 3D food printers available on the market, each with its own set of features and capabilities.

Research the options and select a printer that best fits your business needs and budget.

2. Develop or source 3D food designs:

Create your own 3D food designs using specialized software, or source pre-made designs from online platforms.

Ensure that the designs are compatible with your chosen 3D food printer.

3. Select appropriate ingredients:

3D food printers typically use edible materials such as chocolate, dough, or pureed ingredients.

Choose high-quality ingredients that are suitable for 3D printing and meet your customers’ dietary preferences and restrictions.

4. Train staff:

Ensure that your staff is trained in operating the 3D food printer and understands the intricacies of 3D food design and production.

5. Promote your 3D printed food offerings:

Market your unique 3D printed food creations to attract customers and set your business apart from competitors.

The Benefits:

- Customization:

3D printed food allows for a high level of customization, enabling businesses to cater to individual customer preferences and dietary requirements.

- Efficiency:

3D food printers can produce intricate designs and shapes more quickly and accurately than traditional food preparation methods.

- Innovation:

Embracing 3D printed food demonstrates a commitment to innovation and cutting-edge technology, which can help businesses stand out in a competitive market.

- Sustainability:

3D printed food has the potential to reduce food waste by allowing for precise portion control and the use of alternative, sustainable ingredients.

Take Initiative

Culinary Applications for 3D Printing

Food Ink - World’s First 3D-Printing Restaurant

Natural Machines Foodini - Edible 3D Printer

The 3D Food Printing Conference

14. Eco-friendly products made from recycled materials

In today’s environmentally conscious world, there is a growing demand for sustainable products.

One way to meet this demand is by creating eco-friendly items using recycled materials and 3D printing technology.

This business idea involves leveraging the sustainability aspect of 3D printing to produce items made from recycled materials like plastic waste or biodegradable filaments.

Key Steps to Success:

1. Research and choose the right materials:

Look for recycled materials that can be used as 3D printing filaments, such as PET plastic from bottles, PLA (polylactic acid) made from renewable resources like cornstarch, or even biodegradable filaments like algae-based materials.

2. Invest in a 3D printer:

Purchase a 3D printer that can handle the chosen materials.

Some printers are specifically designed for eco-friendly filaments, while others may require modifications or upgrades.

3. Design or source product ideas:

Create your own designs or source existing ones from online repositories.

Consider items that have a broad appeal and can be easily customized, such as phone cases, planters, or reusable shopping bags.

4. Market your products:

Build a brand around sustainability and eco-friendliness.

Use social media, online marketplaces, and local events to showcase your products and reach potential customers.

The Benefits:

- Growing demand for sustainable products:

Consumers are increasingly looking for eco-friendly alternatives to traditional products, and businesses that cater to this demand can tap into a growing market.

- Reduced production costs:

Using recycled materials can help lower production costs, as they are often cheaper than virgin materials.

- Positive brand image:

Embracing sustainability and eco-friendliness can help build a positive brand image, attracting customers who share these values.

- Environmental benefits:

By using recycled materials and biodegradable filaments, businesses can help reduce plastic waste and contribute to a cleaner environment.

Take Initiative

Guide to Eco-Friendly Filaments

Sculpteo Sustainability Initiatives

Eco-friendly 3D printing materials guide

How to start a 3D printing business

15. Rapid Prototyping and Custom Design Services

Prototyping and design services, including rapid prototyping with 3D printing technology, enable businesses to efficiently develop and refine product ideas, create personalized items, and offer small-batch or limited-edition products.

This approach reduces time-to-market, improves product quality, and caters to niche markets, setting businesses apart from competitors and increasing their chances of success.

Key Steps to Success:

1. Research and invest in 3D printing technology:

Invest in high-quality 3D printers and materials suitable for various types of projects, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) printers.

Research the best options for your needs and budget.

2. Develop a strong skill set:

Gain expertise in design tools such as Computer-Aided Design (CAD) software, 3D printing, and other prototyping technologies.

A strong foundation in design principles, materials, and manufacturing processes is also essential.

3. Create a portfolio:

Showcase your design and prototyping skills by developing a diverse catalogue of products.

This will help potential clients understand your capabilities and the value you can bring to their projects.

Consider offering a variety of materials, colors, and designs to appeal to a wide range of customers.

4. Establish a streamlined process:

Create a workflow for receiving client designs, reviewing and optimizing them for 3D printing, and producing prototypes in a timely manner.

5. Establish a network:

Connect with local businesses, startups, and entrepreneurs who may require prototyping and design services.

Attend industry events, join online forums, and participate in local meetups to expand your network.

6. Develop a pricing model:

Determine a pricing structure for your services, considering factors such as project complexity, materials, and time investment.

Offer flexible pricing options to cater to different client needs and budgets.

7. Market your services:

Create a professional website, use social media, and leverage your network to promote your prototyping and design services.

Advertise your rapid prototyping services to businesses in industries such as automotive, aerospace, medical, and consumer products.

The Benefits:

- Faster time-to-market:

Rapid prototyping and design services can help businesses bring their products to market more quickly.

This allows businesses to test and refine their designs quickly, reducing the time it takes to develop a product.

- Cost savings:

3D printing can be more cost-effective than traditional manufacturing methods, especially for small-scale production and complex designs.

By identifying design flaws and making improvements during the prototyping phase, businesses can save money on costly revisions and manufacturing errors.

- Improved product quality:

Rapid prototyping enables businesses to identify and address design flaws early in the development process, resulting in a higher-quality final product.

- Competitive advantage:

Leveraging the expertise of prototyping and design professionals can give businesses a competitive edge by enabling them to create innovative and well-designed products.

- Customization:

3D printing technology allows for greater design flexibility and customization, enabling businesses to create unique and innovative products.

- Increase customer satisfaction:

By providing tailored solutions, businesses can cater to individual preferences and ensure that customers are satisfied with their purchases.

- Boost brand loyalty:

When customers receive a high-quality personalized product that meets their needs and preferences, they are more likely to become repeat customers and recommend the business to others.

Take Initiative

Ultimaker’s Guide to Rapid Prototyping

Ultimaker: A Guide to 3D Printing Technologies

3D Hubs: The 3D Printing Handbook

Sculpteo: Rapid Prototyping Guide

16. 3D Printed Prosthetics and Orthotics

The business idea revolves around providing custom-fit, affordable prosthetics and orthotics using 3D printing technology.

This innovative approach aims to improve the lives of people with mobility issues by offering them personalized, high-quality, and cost-effective solutions.

Key Steps to Success:

1. Research and development:

Invest time and resources in understanding the needs of the target market and the latest advancements in 3D printing technology.

Collaborate with medical professionals, engineers, and designers to develop functional and aesthetically pleasing prosthetics and orthotics.

2. Acquire 3D printing equipment:

Purchase or lease high-quality 3D printers specifically designed for creating prosthetics and orthotics.

Ensure that the printers are capable of using biocompatible materials.

3. Develop a digital library of designs:

Create a comprehensive digital library of customizable prosthetic and orthotic designs.

Offer a wide range of options to cater to the diverse needs of clients.

4. Establish a fitting and customization process:

Develop a seamless process for measuring clients’ limbs, customizing the designs, and fitting the final products.

This may involve using 3D scanning technology and working closely with medical professionals.

5. Marketing and promotion:

Build a strong online presence, attend industry events, and collaborate with healthcare providers to promote the business and reach potential clients.

The Benefits:

- Growing market demand:

With an increasing number of people requiring prosthetics and orthotics, there is a significant market demand for affordable and personalized solutions.

- Technological advancements:

The rapid advancements in 3D printing technology make it possible to produce high-quality, custom-fit prosthetics and orthotics at a fraction of the traditional cost.

- Competitive advantage:

Offering 3D printed prosthetics and orthotics can set a business apart from competitors and position it as an innovative and forward-thinking provider in the industry.

- Social impact:

By providing affordable and accessible prosthetics and orthotics, businesses can make a positive impact on the lives of people with mobility issues, helping them regain independence and improve their quality of life.

Take Initiative

3D Systems Healthcare Solutions

Open Bionics - Affordable Prosthetic Limbs

e-NABLE Community for 3D Printed Prosthetics

17. Customized Foodservice Items and Kitchenware

Customized foodservice items and kitchenware involve the creation of unique and personalized 3D printed items for restaurants, cafes, or home kitchens.

These items can include customized cookie cutters, cake molds, serving utensils, and more.

This business idea caters to the growing demand for personalization and uniqueness in the food industry, allowing businesses to stand out from the competition and create memorable experiences for their customers.

Key Steps to Success:

1. Research and identify your target market:

Determine the types of businesses or individuals who would be interested in customized kitchenware and foodservice items, such as bakeries, cafes, restaurants, or home cooks.

2. Invest in 3D printing technology:

Purchase or lease a 3D printer and learn how to use it effectively.

You may also need to invest in design software to create digital models of your products.

3. Create a portfolio of designs:

Develop a range of unique and customizable designs for your target market.

This may include different shapes, sizes, and styles of cookie cutters, cake molds, and serving utensils.

4. Promote your business:

Market your products through social media, online marketplaces, and local events.

You can also approach businesses directly to offer your services.

5. Fulfill orders and provide excellent customer service:

Ensure that you can produce high-quality products in a timely manner and maintain strong communication with your customers.

The Benefits:

- Stand out from the competition:

Customized foodservice items and kitchenware can help businesses differentiate themselves from competitors and create a unique brand identity.

- Enhance customer experience:

Personalized items can create memorable experiences for customers, increasing the likelihood of repeat business and positive word-of-mouth marketing.

- Increase revenue:

Offering customized products can allow businesses to charge a premium for their unique offerings, increasing overall revenue.

- Improve efficiency:

3D printing technology can help businesses produce customized items quickly and efficiently, reducing the need for large inventories and minimizing waste.

Take Initiative

Ultimaker: 3D Printing in the Food Industry

3Dnatives: Top 10 Applications of 3D Printing in the Food Industry

Sculpteo: 3D Printing for Kitchenware

All3DP: 3D Printed Kitchen Gadgets – 10 Great Curated Models to 3D Print

Tinkercad: Free Online 3D Design Software

Shapeways Custom Cookie Cutters

18. Restoration and Preservation Services

Restoration and preservation services using 3D printing technology focus on the accurate and efficient repair or conservation of historical artifacts, sculptures, and architectural elements.

By leveraging the power of 3D printing, these services can recreate missing or damaged parts with high precision and minimal damage to the original piece, ensuring the longevity and integrity of our cultural heritage.

Key Steps to Success:

1. Assessment and Scanning:

Begin by assessing the artifact, sculpture, or architectural element to determine the extent of damage or deterioration.

Use 3D scanning technology to create a digital model of the object, capturing its intricate details and dimensions.

2. Digital Restoration:

Use specialized software to manipulate the digital model, repairing any damage or filling in missing parts.

This process may involve collaboration with historians, archaeologists, or other experts to ensure accuracy and authenticity.

3. 3D Printing:

Once the digital restoration is complete, use a 3D printer to create a physical replica of the restored object.

Depending on the material and complexity of the piece, this may involve using various 3D printing techniques, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), or Selective Laser Sintering (SLS).

4. Integration and Finishing:

Carefully integrate the 3D printed parts with the original artifact, ensuring a seamless and secure fit.

Apply any necessary finishing touches, such as painting or polishing, to match the appearance of the original piece.

The Benefits:

- Preserve Cultural Heritage:

By restoring and preserving historical artifacts, businesses contribute to the conservation of our shared cultural heritage, ensuring future generations can appreciate and learn from these invaluable pieces.

- Attract Clients and Funding:

Offering cutting-edge restoration and preservation services can attract clients, such as museums, galleries, and private collectors, as well as secure funding from government agencies or cultural organizations.

- Innovative Niche Market:

As 3D printing technology continues to advance, businesses specializing in restoration and preservation services can establish themselves as leaders in an innovative and growing niche market.

Take Initiative

3D Printing in Cultural Heritage: A Guide to Good Practice

3D Scanning for Heritage Preservation

How 3D Printing is Changing Art Restoration

Sculpteo’s Guide to 3D Printing Technologies

Sculpteo Art & Sculpture Restoration Services

Shapeways Cultural Heritage Marketplace

International Council on Monuments and Sites (ICOMOS)

19. Build a 3D Printing Community to Collaborate with Local Artists and Designers

Building a community to collaborate with local artists and designers can promote your 3D printing business while supporting local talent, creating unique, exclusive products that showcase their skills and your capabilities.

Partnering with creative professionals in your community allows for a diverse range of 3D printed products catering to various interests, ultimately expanding your customer base, increasing sales, and boosting your city’s economy and involvement in 3D printing technologies.

Key Steps to Success:

1. Identify local artists and designers:

Research and connect with local artists, designers, and other creative professionals in your community who have a unique style or a strong following.

Look for those who are open to collaboration and have an interest in 3D printing.

2. Reach out and propose a collaboration:

Contact the artists and designers you’ve identified and propose a partnership.

Explain the benefits of working together, such as increased exposure and the opportunity to create innovative products.

3. Organize networking events:

Host events, workshops, or meetups to bring together local artists, designers, and 3D printing enthusiasts.

This will help create a sense of community and provide a platform for collaboration.

4. Develop a project plan:

Once you’ve found interested partners, work together to develop a project plan that outlines the scope, timeline, and responsibilities of each party.

This will help ensure a smooth collaboration process.

This may involve brainstorming sessions, sketching, and digital design work.

Once the designs are finalized, create prototypes to test the functionality and aesthetics of the products.

5. Develop partnerships:

Reach out to local artists and designers to discuss potential collaboration opportunities.

Offer your 3D printing services to help them bring their ideas to life, and work together to create unique and innovative products.

6. Promote the collaboration and sell your products:

Launch a marketing campaign to promote the exclusive 3D printed products.

Showcase the exclusive 3D printed products on your website, social media, at in-store displays, and local events.

Share the stories behind the collaborations and highlight the local talent involved. Sell the products through your online store, physical location, or other relevant channels.

7. Expand the community:

Continuously seek out new artists and designers to collaborate with, and encourage existing partners to refer others to your business.

The Benefits:

- Support local talent:

Collaborating with local artists and designers helps promote their work and contributes to the growth of your community’s creative scene.

- Increase brand visibility:

Unique and innovative 3D printed products will attract attention and help your business stand out from competitors.

Partnering with well-known artists and designers can further increase your business’s visibility and credibility, as their followers may become interested in your products and services.

- Strengthen community ties:

By actively engaging with and supporting local artists and designers, your business will become an integral part of the community and foster goodwill among residents.

- Diversify product offerings:

Working with a variety of creative professionals will result in a diverse range of 3D printed products that stand out in the market, appealing to a wider audience and increasing sales potential.

- Encourage innovation:

Collaborating with artists and designers can lead to new ideas and techniques in 3D printing that combine art, design, and technology in new and exciting ways.

By pushing the boundaries of what’s possible you can keep your business at the forefront of the industry.

Take Initiative

20. Create Molds for Casting Using 3D Printing

Utilize 3D printing technology to create intricate molds for metal casting or resin pouring in industries like jewelry-making, sculpture, and product design.

This business idea involves providing custom mold designs and manufacturing services to clients who require unique, high-quality molds for their projects.

Key Steps to Success:

1. Research and invest in a 3D printer:

Choose a 3D printer that can handle the materials and level of detail required for creating molds.

Look for printers that support high-resolution printing and are compatible with various materials, such as wax or resin.

2. Learn 3D modeling software:

Familiarize yourself with 3D modeling software like Blender, Tinkercad, or Fusion 360.

These tools will allow you to create custom designs for your clients’ molds.

3. Create a portfolio:

Develop a portfolio showcasing your mold designs and finished products.

This will help potential clients understand your capabilities and the quality of your work.

4. Market your services:

Reach out to businesses and individuals in industries like jewelry-making, sculpture, and product design.

Attend trade shows, join online forums, and network with potential clients to promote your services.

5. Manage orders and production:

Streamline your order management and production process to ensure timely delivery of high-quality molds to your clients.

The Benefits:

- Customization:

3D printing allows for greater customization, enabling businesses to create unique and intricate designs that would be difficult or impossible to achieve with traditional mold-making techniques.

- Cost-effectiveness:

3D printing can be more cost-effective than traditional mold-making methods, especially for small-scale production or one-off pieces.

- Speed:

3D printing technology can significantly reduce the time it takes to create a mold, allowing businesses to bring their products to market more quickly.

- Sustainability:

3D printing can reduce material waste and energy consumption compared to traditional mold-making methods, making it a more environmentally friendly option.

Take Initiative

Ultimaker: 3D Printing for Molds and Casting

All3DP: How to 3D Print Molds for Small Batch Manufacturing

Formlabs: 3D Printing for Investment Casting

Sculpteo: 3D Printing for Jewelry

21. Custom Cookie Cutters and Baking Tools

Custom cookie cutters and baking tools are a unique and innovative way to cater to the needs of baking enthusiasts and professionals alike.

By offering personalized designs and on-demand production, businesses can tap into a niche market that values creativity and customization.

This business idea involves using 3D printers to create food-safe cookie cutters, cake toppers, and other baking tools that can be tailored to the specific needs and preferences of customers.

Key Steps to Success:

1. Invest in a 3D printer:

To start, you’ll need a 3D printer capable of printing with food-safe materials.

Research different models and choose one that fits your budget and production needs.

2. Select food-safe materials:

Ensure that the materials you use for printing are food-safe, such as PLA (Polylactic Acid) or PETG (Polyethylene Terephthalate Glycol).

These materials are non-toxic and can be used safely in contact with food.

3. Create or source designs:

Develop your own unique designs or source them from online platforms like Thingiverse or MyMiniFactory.

You can also collaborate with designers to create custom designs for your customers.

4. Set up an online store:

Create an online store to showcase your products and make it easy for customers to place orders.

Offer customization options, such as allowing customers to upload their own designs or choose from a range of pre-made templates.

5. Market your business:

Use social media, online forums, and local events to promote your business and showcase your unique products.

Collaborate with local bakeries, cooking schools, or event planners to expand your reach.

The Benefits:

- Niche market:

Custom cookie cutters and baking tools cater to a niche market of baking enthusiasts and professionals who value creativity and personalization.

This can help set your business apart from competitors.

- On-demand production:

3D printing allows for on-demand production, reducing the need for inventory and storage space.

This can help keep costs low and increase efficiency.

- Customization:

Offering customization options can attract customers who are looking for unique, personalized products that reflect their interests and tastes.

- Environmentally friendly:

Using eco-friendly materials like PLA can help reduce the environmental impact of your business and appeal to eco-conscious customers.

Take Initiative

Food-safe 3D printing materials guide

Marketing strategies for small businesses

22. Integrate VR/AR Technologies with 3D Printing

The integration of virtual reality (VR) and augmented reality (AR) technologies with 3D printing is an innovative approach to enhance customer experience and streamline the design process.

By combining these cutting-edge technologies, businesses can offer clients the ability to visualize and interact with their custom designs before they are printed, leading to increased satisfaction and reduced production costs.

Key Steps to Success:

1. Research:

Identify the most suitable VR/AR platforms and software for your specific 3D printing applications.

2. Invest in VR/AR hardware and software:

To get started, businesses will need to invest in VR/AR headsets and compatible software.

There are several options available, such as the Oculus Rift, HTC Vive, and Microsoft HoloLens.

3. Develop or source 3D models:

Create or source 3D models that can be used in the VR/AR environment.

These models should be compatible with the chosen VR/AR software and optimized for performance.

4. Hire employees:

Train your team in using VR/AR technologies and integrate them into your sales and design processes.

5. Implement a user-friendly interface:

Develop an intuitive user interface that allows clients to easily navigate and interact with the 3D models in the VR/AR environment.

6. Integrate with existing 3D printing services:

Ensure seamless integration between the VR/AR experience and the 3D printing process.

This may involve developing custom software or partnering with existing 3D printing service providers.

7. Promote the service:

Market the new VR/AR-enhanced 3D printing service to potential clients, showcasing the benefits of this innovative approach.

Promote your VR/AR capabilities as a unique selling point to attract new customers and differentiate yourself from competitors.

The Benefits:

- Improved customer satisfaction:

Allowing clients to visualize and interact with their designs before they are printed can lead to increased satisfaction, as they can make adjustments and ensure the final product meets their expectations.

- Reduced production costs:

By identifying and addressing design issues before printing, businesses can minimize wasted materials and reduce the need for costly reprints.

- Competitive advantage:

Offering a unique, immersive design experience can help businesses stand out in the crowded 3D printing market and attract new clients.

Additionally, offering cutting-edge technology solutions can help position your business as an innovative leader in the industry.

- Streamlined design process:

Integrating VR/AR technologies can help streamline the design process, as clients can quickly and easily make adjustments to their models in real-time.

This reduces the need for physical prototypes, saving time and resources.

- Enhanced customer experience:

Integrating VR/AR technologies can enhance customer experience by providing a more interactive and engaging way to visualize and customize 3D printed products.

Take Initiative

How Virtual Reality is Transforming the 3D Printing Industry

Augmented Reality for 3D Printing: A Practical Use Case

The Future of 3D Printing and Augmented Reality

Microsoft HoloLens for Business

23. Customized Protective Cases for Electronics

Customized electronics enclosures are a niche market that focuses on providing tailored protective cases and components for various electronic devices, such as Raspberry Pi cases, drone components, and other DIY electronic projects.

By using 3D printing technology, businesses can create unique and personalized enclosures that cater to specific customer requirements, offering a competitive edge in the market.

Key Steps to Success:

1. Research the market:

Understand the needs and preferences of your target audience, including the types of devices they use and the features they require in an enclosure.

2. Invest in 3D printing technology:

Acquire a high-quality 3D printer and learn how to use it to create customized enclosures.

This may involve learning CAD software to design the enclosures and mastering the 3D printing process.

3. Develop a product portfolio:

Create a range of enclosure designs that cater to different devices and customer preferences.

Offer customization options, such as color, material, and additional features like cooling systems or mounting options.

4. Promote your business:

Market your customized electronics enclosures through various channels, such as social media, online forums, and trade shows.

Build a strong online presence with a user-friendly website showcasing your products and services.

The Benefits:

- Meet customer needs:

Customized electronics enclosures cater to the specific requirements of customers, providing a unique selling point and setting your business apart from competitors.

- Leverage emerging technology:

3D printing technology is becoming more accessible and affordable, allowing businesses to create high-quality, customized products with lower production costs.

- Expand product offerings:

By offering a range of enclosure designs and customization options, businesses can attract a wider customer base and increase sales.

- Stay ahead of the competition:

As the electronics market continues to grow, businesses that offer innovative and personalized solutions will have a competitive advantage.

Take Initiative

3D Printing for Electronics Enclosures: A Guide

24. Personalized Gifts and Souvenirs

Personalized gifts and keepsakes are unique, thoughtful, and memorable items that can be customized to suit the recipient’s taste, personality, or interests.

These items can range from ornaments, photo frames, and figurines to jewelry, clothing, and home decor.

By offering a range of customizable gift items, businesses can cater to a wide audience, create a niche market, and establish a loyal customer base.

Key Steps to Success:

1. Identify your target market:

Determine the demographic you want to cater to, such as couples, families, pet owners, or hobby enthusiasts.

2. Choose the products:

Select a range of gift items that can be easily customized using techniques like 3D printing, laser engraving, or embroidery.

3. Find suppliers:

Source high-quality materials and products from reliable suppliers or manufacturers.

You may also consider partnering with local artisans or craftsmen.

4. Invest in customization equipment:

Purchase the necessary equipment for personalization, such as 3D printers, laser engravers, or embroidery machines.

5. Create an online presence:

Develop a user-friendly website or e-commerce platform that showcases your products and allows customers to easily customize and order their gifts.

6. Promote your business:

Utilize social media, email marketing, and online advertising to reach your target audience and showcase your unique offerings.

The Benefits:

- Increased customer satisfaction:

Personalized gifts show thoughtfulness and effort, leading to higher customer satisfaction and positive word-of-mouth marketing.

- Higher profit margins:

Customized products often command a premium price, resulting in higher profit margins for businesses.

➤ MORE: Download our FREE guide to Pick the Perfect Price Point!

- Brand differentiation:

Offering personalized gifts sets your business apart from competitors and helps create a unique brand identity.

- Customer loyalty:

Unique and memorable gifts can lead to repeat business and a loyal customer base.

- Niche market:

Catering to a specific demographic or interest group can help businesses carve out a niche market with less competition.

Take Initiative

25. Adaptive Clothing Solutions

Adaptive clothing solutions focus on designing and producing clothing and accessories that cater to the unique needs of individuals with disabilities or special needs.

By utilizing 3D printing technology, businesses can create innovative fasteners and assistive devices that make dressing and undressing easier, more comfortable, and more efficient for those who need it.

Key Steps to Success:

1. Research and identify the needs: